The FGOIC TI technology

Patented method for Titanium coated PEEK cages

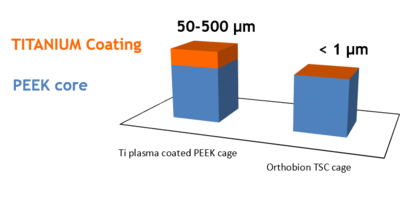

TSC Cages consist of a composite PEEK/Titanium implant with a biomimetic imprint. Our proprietary Titanium Fine Grained Osseo Integrative Coating technology (FGOIC Ti) allows for optimal interaction between biomaterials and bioenvironment, granting all the advantages of PEEK and Titanium, and no downsides.

The Titanium layer on TSC cages, with a thickness of less than 1µm, is 1.000 times thinner than layers deposited with plasma coating.

Design benefits

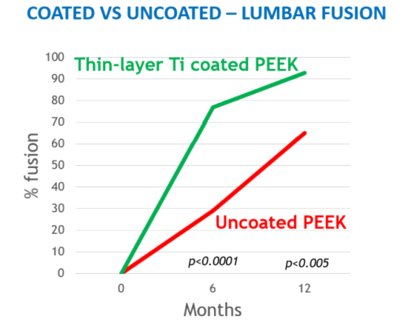

Perfect fusion

Titanium, used in the surface layer of TSC Cages, is traditionally considered one of the best choices for biotompatible implants, since it promotes osteoblasts recruitment, maturation and differentiation: using it as an interface between the implant and bone tissue results in perfect fusion, which will be achieved faster than with polymeric materials eliminating the risk of fibrotic tissue generation on the contact surface.

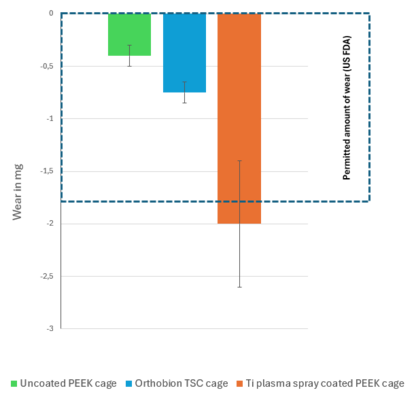

Stress resistance

The risk of flaking and other side effects of wearing is substantially lower with TSC Cages than with composite implants manufactured with traditional methods: FGOIC Ti technology allows for the production of a Titanium layer which is 1.000 times thinner than plasma coating, resulting in a better resistance to stress and eliminating the risks associated with the usage of traditional composite solutions.

Radiolucency

The thin layer of Titanium, along with the radiolucent markers embedded into the implants, also provides for better compatibility with Imaging techniques: the position of TSC Cages can be easily detected during and after the surgery, to ensure proper positioning and monitoring with no visual artifacts.

Optimal mechanical characteristics

The thin PEEK core of TSC Cages provides them with optimal mechanical properties: since the elastic modulus of PEEK is substantially lower than Titanium, the load transfer between bone and implant is favoured, reducing the risk of shield effect and subsidance.